3d Metal Printing Machine: Everything You Need To Know

It’s critical to understand the function of a 3D printer if you’re considering purchasing a Metal 3D printer for the first time. In keeping with its moniker, 3d metal printing machine the creation of three-dimensional objects. An Additive Manufacturing machine or 3D printer is used to create a three-dimensional solid item by printing a 3D model from a CAD program.

Is it beneficial to use 3D printing?

Businesses are embracing 3D printing for a variety of reasons. This method is not only cutting-edge, but it is also convenient. Using 3D printing has the following advantages:

- Complex designs are simpler to produce

Complex designs may be created with ease with 3D printing. Additive Manufacturing is most effective when product owners use it to develop their components.

- It improves the architecture

3D printing allows you to have complete control over the final product for metals. It is possible to tailor your model’s form and structure while still completing the chores that would otherwise be insurmountable

- It allows for the mass production of customized products

3D printing makes it feasible to edit an existing design in your program and print a new model each time you need a personalized plan.

- Achieve more effective while spending less money

Using conventional techniques will be costly if your company has to make small quantities of 3D models. Even in these instances, 3D printing is an affordable solution. Additionally, the rapid 3D printing technique saves product development and manufacturing time.

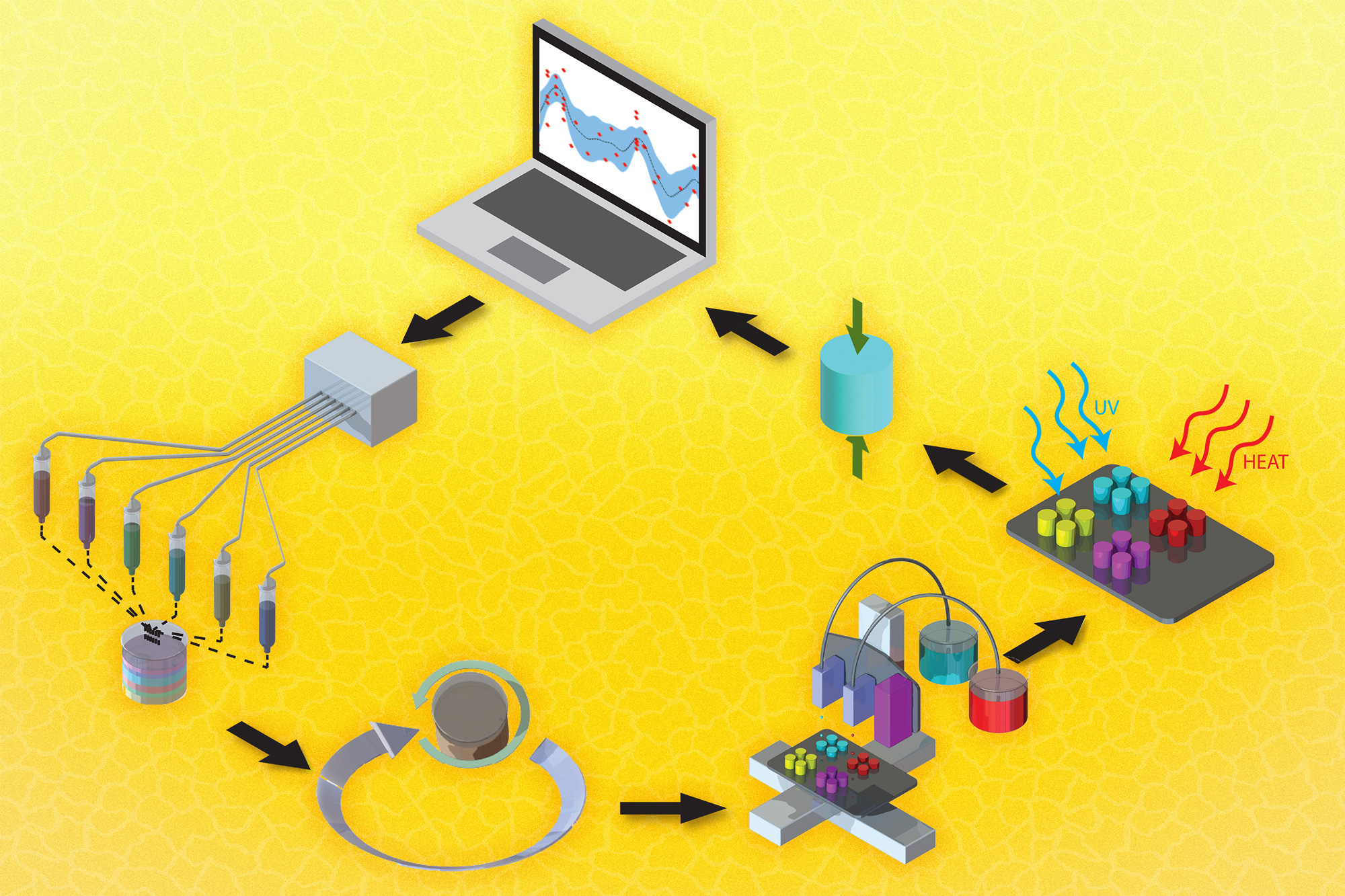

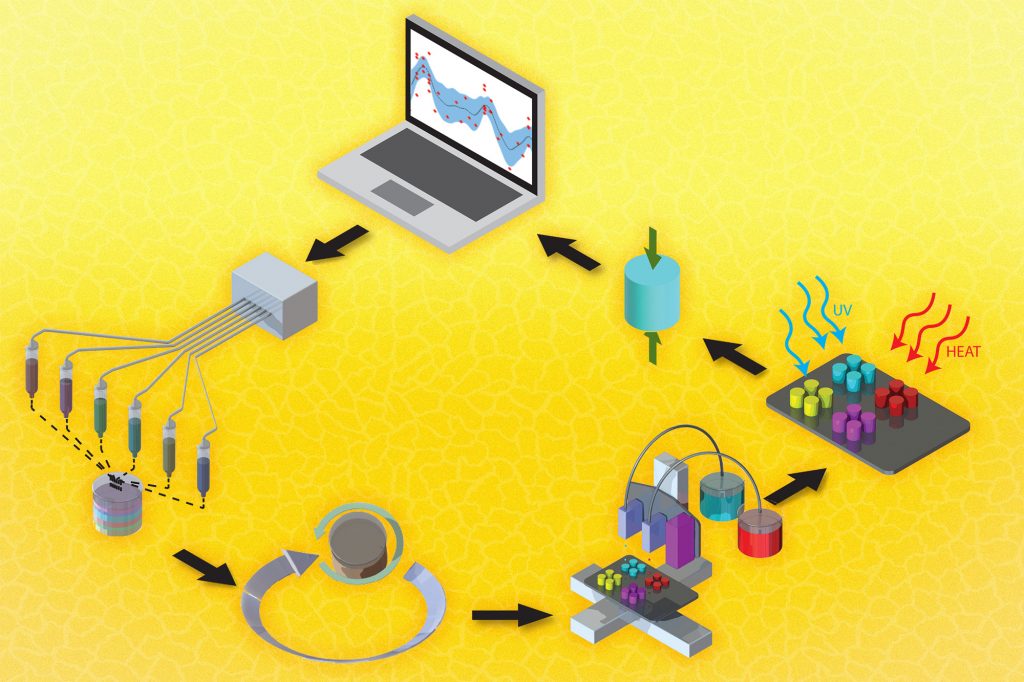

In additive manufacturing, the final model is constructed by building up successive layers of material

For intricate structures that would otherwise be hard to create using traditional manufacturing methods, a metal 3d metal printing machine is a viable alternative. Because the systems are exceptionally light and sturdy, functional optimization and integration may be achieved without extra assembly procedures. Layer by layer, the powdered material is fused based on a CAD model to create a three-dimensional item.